Maintenance

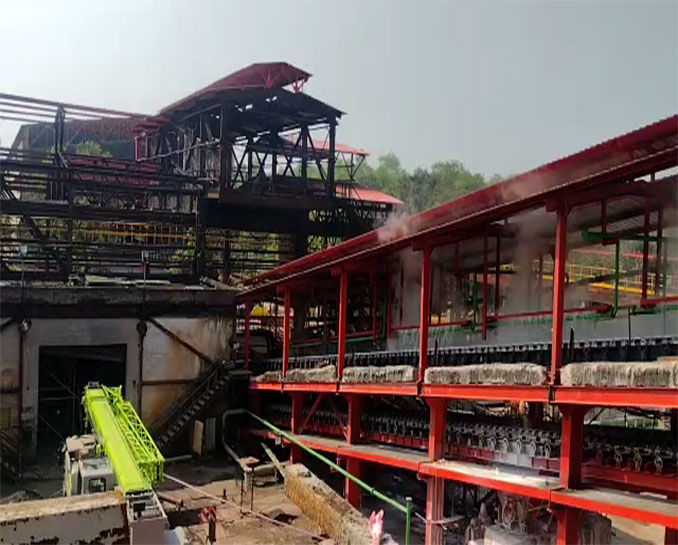

This involves the maintenance, repair, and troubleshooting of mechanical equipment used in the production process, including specialized machinery used in blast furnaces, steel mills, and rolling mills. In a steel plant, mechanical maintenance is critical to ensuring that the plant operates at peak efficiency and produces high-quality steel products.

Maintenance tasks include regular inspections, lubrication, cleaning, and replacement of worn or damaged components. In addition to performing routine maintenance tasks, mechanical maintenance professionals must also have the ability to diagnose and troubleshoot problems with mechanical equipment promptly and effectively.

These jobs require working under pressure and prompt action during emergencies to minimize downtime and preserve the production schedule. The ability to work efficiently and safely is crucial to ensure the equipment’s flawless functioning and prevent any hazardous incidents.

SHUTDOWN MANAGEMENT

Shutdown management involves planning, coordinating, and executing maintenance and service activities during a scheduled plant shutdown. These shutdown periods are critical for carrying out maintenance work that cannot be performed during normal operations. Effective shutdown management is crucial to minimize downtime, maximize plant efficiency, and ensure the safety of workers.

In a steel plant, shutdown management typically involves a detailed planning process, including determining the scope of work, creating a schedule, identifying required resources and materials, and allocating resources and manpower. Communication and coordination among various departments and teams involved in the shutdown is also essential for a smooth and successful process.

After the shutdown, a post-shutdown review is conducted to evaluate the success of the shutdown and identify areas for improvement in future shutdowns. This review is important for continuous improvement and ensuring that future shutdowns are executed more efficiently and effectively.